Cold Weather Maintenance and Best Practices

If you’re anything like me, you have the best intentions when you purchase new tools and equipment. You’re going to take good care of them. You’re going to keep them clean. Blades will stay sharp, parts will be lubricated regularly, and everything will be put in its proper place at the end of the day.

And then reality sets in.

Suddenly you’re standing in front of a garage, shop or trailer full of tools that need some level of care. So, how do you keep track of it all? The answer, of course, is to keep a detailed maintenance log.

As a general rule of thumb, any piece of equipment should include a maintenance schedule like the one we have published here and in our owner’s manual. A comprehensive maintenance log should include all of the recommendations from each manufacturer, organized into daily, weekly, monthly and yearly tasks. This can be done on paper or using a computer spreadsheet.

If you live in a Northern climate, however, you know your maintenance routine gets a little more complicated when temperatures drop. To help you keep your air compressor running smoothly, we’ve assembled the following list of cold weather maintenance best practices.

COLD WEATHER MAINTENANCE

Synthetic Oil

Most of our models ship with a blended synthetic air compressor oil in the pump crankcase. However, if you have an older air compressor or a model that has standard summer weight oil, we highly recommend switching to a full synthetic or blended synthetic air compressor oil. This type of oil maintains proper viscosity in a greater temperature range. As an added bonus, you can go longer between oil changes. Check out the table below for more information on the different types of synthetic compressor oil we offer.

| Oil Type | Temperature Range | Change Interval |

|---|---|---|

| ROLAIR® Blended Synthetic | -5° to 120°F (-20° to 50°C) | 1,000 – 2,000 hours |

| ROLAIR® Full Synthetic | -5° to 120°F (-20° to 50°C) | 3,000 – 4,000 hours |

Clean Exterior

Cleaning may not fit your definition of preventative maintenance, but it should. Fall is a great time to clean off all the mud and dust that accumulated during the Spring and Summer. Keeping your air compressor reasonably clean can help prevent corrosion and make it easier to spot oil leaks. It also gives you an opportunity to visually inspect all of your air compressor’s components for signs of wear and tear.

Check Rubber Feet

Frequent use in cold environments can really speed up the wear and tear of your air compressor’s rubber feet. Keep a close eye on them. While it may seem like a minor detail, worn or broken rubber feet can cause excessive vibration, which can lead to some major problems.

COLD WEATHER BEST PRACTICES

Store Indoors

Start off on the right foot by keeping your air compressor at room temperature when not in use. Doing so will decrease the likelihood of leftover moisture freezing in the system. It will also allow the oil to stay at the proper viscosity, making start-up easier.

Of course, we realize that it’s not always possible to keep equipment in a temperature controlled environment. If you’re in the middle of a big framing job, chances are the equipment is being stored in a trailer in the evening. If you follow the rest of the advice in this post, you shouldn’t have trouble getting started in the morning.

Drain Tank(s)

We recommend doing this all year round. The primary reason is to keep your air compressor’s tanks from rusting prematurely. In the winter, however, this practice will also help prevent your air lines from freezing.

Start Unloaded

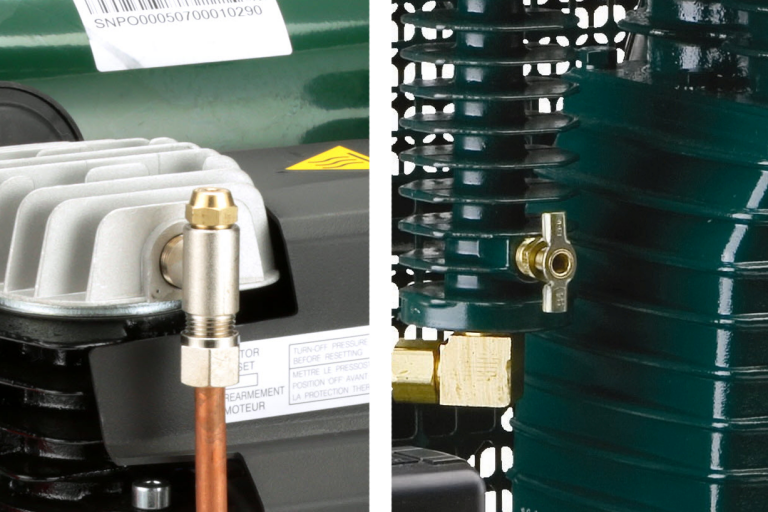

Many of our models feature a cold start valve on the aftercooler or discharge tube. This valve opens manually or automatically to relieve system pressure at start-up. If you’re model does not have this feature, you can achieve the same affect by starting your air compressor with the tank drain(s) open. Just be sure to close them after the machine has had a chance to warm up (approximately 30-45 seconds). For a video tutorial on how to start an air compressor in cold weather, click here.

Don’t let cold weather slow you down. Follow the recommendations in this post to keep your air compressor in shape year-round. If you have any questions or concerns about cold weather maintenance and operation, drop us a line at (920) 349-3281, email us at sales@rolair.com or direct message us on Facebook or Instagram.

How do you keep your job site running smoothly in cold weather? It doesn’t have to be air compressor related. Share your best tricks and tips in the comments section below.