- Home

- /

PMP22K28CH

PMP22K30CH

ROLAIR PARTS & PRICING

Our distributors have access to a huge variety of ROLAIR repair parts and accessories. Enter a part number below to view current list price. If you need help determining a part number, check out our compressor and pump schematics. Download a PDF version of our Parts List.

Download Schematics

Hand Carry

A Wide Variety of Direct Drive Hand Carry Air Compressor

| Model Number | |

|---|---|

| VT20ST | VT20ST Schematic |

| VT20TB | VT20TB Schematic |

| VT25BIG | VT25BIG Schematic |

| FC250090L | FC250090L Schematic |

| D2002HPV5 | D2002HPV5 Schematic |

| GD5000PV5H | GD5000PV5H Schematic |

| JC10PLUS | JC10PLUS Schematic |

| AB5PLUS | AB5PLUS Schematics |

| JC20 | JC20 Schematic |

| FC1500HS3 | FC1500HS3 Schematic |

| FC2002 | FC2002 Schematic |

| FC2002HBP6 | FC2002HBP6 Schematic |

Wheeled Electric

1.5 to 5 HP Electric Belt Drive Portable Air Compressors

| Model Number | |

|---|---|

| 3095K18 | 3095K18 Schematic |

| 3230K24CS | 3230K24CS Schematic |

| 5230K30CS | 5230K30CS Schematic |

| 5520K17A | 5520K17A Schematic |

| 5715K17 | 5715K17 Schematic |

| 5715MK103 | 5715MK103 Schematic |

| 6820K17D | 6820K17 Schematic |

Wheeled Gas

163cc (5.5 HP) to 270 cc (9HP) Gas-Powered Belt Drive Portable Air Compressors

| Model Number | |

|---|---|

| 1040HK18 | 1040HK18 Schematic |

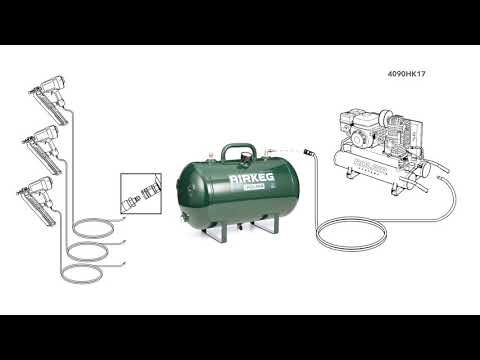

| 4090HK17 | 4090HK17 Schematic |

| 4090HK17/20 | 4090HK17/20 Schematic |

| 4090HMK103 | 4090HMK103 Schematic |

| 6590HK18 | 6590HK18 Schematic |

| 7722HK28 | 7722HK28 Schematic |

| 8230HK30 | 8230HK30 Schematic |

| 8422HK30 | 8422HK30 Schematic |

Stationary Gas

163cc (5.5 HP) to 688cc (20 HP) Gas-Powered Belt Drive Truck Mount Air Compressors

| Model Number | |

|---|---|

| TRUCK MOUNT SERIES | 11-13GR Schematic 11-18 |

Belt Drive - Single Stage

Single Stage Belt Drive Pumps for Repair or OEM Applications.

| Model Number | |

|---|---|

| PMP13PT03AC | PMP13PT03AC Schematic |

| PMP12K17CH | PMP12K17CH Schematic |

| PMP12K18CH | PMP12K18CH Schematic |

| PMP12K35CH | PMP12K35CH Schematic |

| PMP12KEMGCHHU | PMP12KEMGCHHU Schematic |

| PMP12MK103 | PMP12MK103 Schematic |

| PMP12MK113 | PMP12MK113 Schematic |

| PMP12PV02AC | PMP12PV02AC Schematic |

| PMP11K3CH | PMP11K3CH Schematic |

| PMP11K8CH | PMP11K8CH Schematic |

Two Stage - Belt Drive

Two Stage Belt Drive Air Compressor Pumps for Repair or OEM Applications.

| Model Number | |

|---|---|

| PMP24K60CH | PMP24K60CH Schematic |

| PMP24K100CH | PMP24K100CH Schematic |

| PMP22K50CH | PMP22K50CH Schematic |

| PMP22K30CH | PMP22K30CH Schematic |

| PMP22K28CH | PMP22K28CH Schematic |

| PMP22BK119 | PMP22BK119 Schematic |

Direct Drive

Direct Drive Pumps for Repair or OEM Applications.

| Model Number | |

|---|---|

| PMP12JC8 | PMP12JC8 Schematic |

| PMP12JC10PLUS | PMP12JC10PLUS Schematic |

| PMP11MK137FC | PMP12MK137FC Schematic |

| PMP11MK238FI | PMP11MK238FI Schematic |

| PMP11MK246FC | PMP11MK246FC Schematic |

| PMP11SF2500FC | PMP11SF2500FC Schematic |

| PMP11VT20TB | PMP11VT20TB Schematic (Full Compressor) |

| PMP11VT25BIG | PMP11VT25BIG Schematic (Full Compressor) |

| MK200FISH | MK200FISH Schematic |

Warranty

Warranty repairs must be performed by an authorized ROLAIR service center. Use our Service Center Locator to find one near you.

Guarantee

Associate Engineering Corporation warrants that all ROLAIR® compressors will be free of defects in material and workmanship for a period of twelve months from the date of initial retail purchase, or eighteen months from the date of manufacture, whichever may occur first.

Should any failure to conform to this warranty be reported to the company within said period, the company shall, upon purchaser shipping the compressor to our plant transportation prepaid, correct such nonconformity by suitable repair or, at its option, furnish a replacement part F.O.B. our plant.

Associate Engineering Corporation shall not be liable for any unauthorized repairs, replacements, adjustments to the compressors, or the costs of labor performed by the purchaser.

This warranty is expressly in lieu of all other warranties expressed, implied or statutory (including, but not limited to, warranties of merchantability and fitness for purpose) and of any other obligations, and/or liabilities on the part of Associate Engineering Corporation. Associate Engineering Corporation neither assumes nor authorizes any other person to assume for it any other obligations or liability in connection with or with respect to any compressor.

Associate Engineering Corporation shall in no event be liable neither for any consequential, incidental or special damages nor for the improper selection of any compressor for a particular application.

Quality

Associate Engineering Corporation is devoted to continual quality control and thorough research of the products we build. It is our creed to give you, the user, all of the experience and engineering available in the production of every piece of equipment we produce.

Our line covers the complete needs of today’s varied air requirements. Rely on ROLAIR® for all the newest and finest features that are available for the modern compressor.

Download

Frequently Asked Questions

What type of oil should be used in the pump on my ROLAIR compressor?

Please refer to the following oil table. It is extremely important to use oil specifically blended for air compressors. Oil packaged under the ROLAIR name is blended with chemicals that resist foaming, provide excellent wear/corrosion protection, and reduce carbon build up. Accept nothing less than genuine ROLAIR compressor oil. Remember to change the initial factory oil after a break in period of fifty hours. Feel free to contact our service department, service@rolair.com for the names of our closest oil stocking distributors.

What is the difference between standard, semi-synthetic, and full synthetic compressor oil?

First, each grade of ROLAIR compressor oil is blended with an additive package specifically formulated to promote longer life. See FAQ #1. Standard compressor oils have a tighter range of operating temperatures and must be changed more frequently. A Group III synthetic blend and a Group IV full synthetic can be used in a much wider range of temperatures and both provide longer change intervals.

What can I do if my air compressor will not start during periods of colder temperatures?

It is our recommendation, regardless of temperature or oil grade, to start the machine with either an aftercooler or tank drain open and allow the air compressor to run “unloaded” for 30-40 seconds before closing the drain to build tank pressure and cycle normally. If the air compressor still does not run properly repeat procedure or change the pump oil to either a lighter weight or synthetic, see chart above, and repeat the “unloaded” starting procedure. If problem persists contact ROLAIR customer service or your local dealer for additional assistance.

Who should I contact to answer technical questions or obtain troubleshooting assistance?

The customer service staff at our Wisconsin factory is well equipped to provide support for any technical or troubleshooting question you have. Please send an email to service@rolair.com or call 1-920-349-3281 between the hours of 7:00 AM & 4:30 PM CST. A local dealer or service representative may also be able to answer your questions.

What should I look for when inspecting my air intake filters?

First, check the overall integrity of the intake canister. If cracked, broken, or loose replace the complete canister immediately. Next, check the filter element(s) and replace if holes are found or excessively dirty. The inspection of pump and engine oil level, intake filters, vibration dampeners, and belt/bolt tension should be done on a regular if not daily basis.

Can complete air compressors and spare parts be ordered factory direct?

Complete machines and spare parts must be obtained only through our distributor and service network. Please contact our sales or service department if you need help locating an online, local, or service dealer.

What size generator should be used to power my ROLAIR air compressor?

Our air compressors are built with inductive style motors that draw a significant amperage spike during each start. Most generators will not provide this start up requirement and lead to premature capacitor and complete motor failures. Therefore, our recommendation is to completely avoid the use of generators. Motor related failures that occur due to generator use will void the warranty.

How can I obtain an owners manual or parts list for my ROLAIR compressor?

Current production schematics and owners manuals can be obtained on this website. Simply click on Schematics under the Service & Support tab, scroll down, and choose from the model numbers shown. Additional questions or requests on older production machines should be directed to our factory service department.

What is the difference between CFM Displaced & CFM Delivered Air? Which should be used when sizing an air compressor?

CFM Displacement is a theoretical amount and should only be used when making comparisons with other brands that do not provide information on actual delivered air. CFM Delivered is an actual airflow amount rated at a specific pressure and should always be used when sizing an air compressor. If you have questions on the best air compressor for your application please contact our service department at 920-349-3281 or service@rolair.com with details on the tools & equipment you wish to operate.

Why should I purchase a ROLAIR instead of a less expensive high-speed oil less machine?

First, ROLAIR splash-lubricated air compressors have a much longer life expectancy. If properly operated and maintained your ROLAIR is capable of achieving 6,000-8,000 working hours. Compared to most homeowner oil less compressors that are built to provide 200-400 working hours of service the choice is clear. Most of our models are also built with S1 motors rated for continuous duty, unlike many high-speed oil less machines that can only be subjected to 50% duty and must be operated 5 minutes on and 5 minutes off.

Finally, we provide unparalleled customer support. Call us with a question or send an email and do the same with the other brands you are considering. We appreciate your business and look forward to hearing from you.